The Challenge

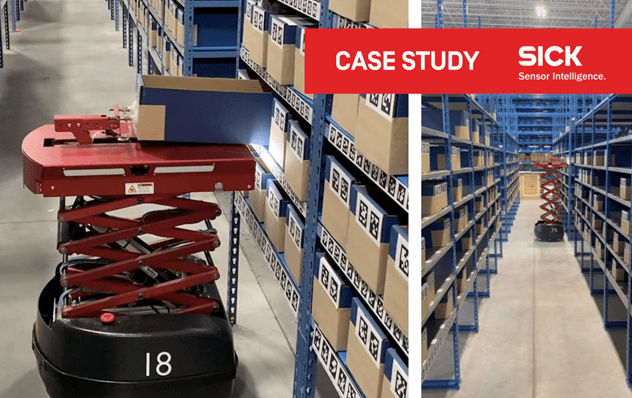

SICK Sensor Intelligence is a leading manufacturer of sensors, safety systems, machine vision, encoders and automatic identification products for industrial applications.

The company needed to increase B2B fulfillment speed and accuracy to ensure timely delivery of products to their growing customer base. They sought a solution to enhance process efficiency and reduce the necessity of hiring additional workers.

They wanted a quick implementation in a brownfield facility that wouldn’t disrupt existing operations and SLA commitments.

SICK was experiencing rapid growth and prioritized flexibility, scalability, and quick ROI as crucial factors in their automation selection process.

“We needed the automation to be flexible, scalable. We needed it to be able to start small, get a win, and then continue to grow. We were looking for a minimum upfront investment to get payback quickly.”

Randy Ross, Head of Supply Chain at SICK

The Result

SICK fulfillment operations saw a 6X productivity increase at the line level and a 10X increase at the unit level, demonstrating the successful integration of automation into SICK’s operations.

The return on investment (ROI) was less than 6 months.

Leave a comment