Why inVia?

-

Twin IQ – Hear what carparts.com has to say

Designed for warehouse environments, Twin IQ zeroes in on processes crucial for workflow optimization, delivering scenario results in just minutes! This is what Michael Huffaker, COO, CarParts.com has to say: “Assessing warehouse efficiency used to consume weeks, even months, of our time and resources. We’d deploy teams of engineers, gather data, and analyze operations extensively to identify areas for…

-

Next Generation Warehouse Intelligence

What if you could eliminate wasted time, keep your operations fine-tuned, and your team always at peak efficiency? Learn how inVia’s intelligent warehouse automation software plans, makes decisions, and assigns tasks to ensure SLA deadlines are always met. Technology | AI Warehouse Automation | inVia Robotics

-

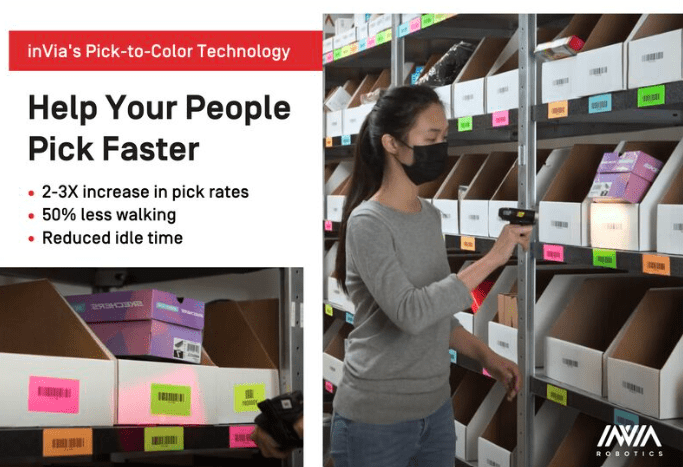

Help your people pick faster

inVia’s Pick-to-Color solution combines the intelligent inVia Logic software and an intuitive color-coding system. While inVia Logic identifies efficient travel paths and optimal batching, people use devices with a color-based interface to follow step-by-step directions. They are intelligently guided through all warehouse tasks to fulfill orders faster. Discover more about inVia’s Warehouse Automation Software here:…

-

Is Robotics as a Service (RaaS) the future of rapid deployment?

With the introduction of Autonomous Mobile Robots (AMRs), whilst cost is now less of a barrier to adoption, one challenge users face is that there are almost too many options given the large diversity in AMR platforms and use cases. Companies are left with trying to determine which are the right platforms to pursue, but…

-

Creating the warehouse of the future

In this webinar we were delighted to hear Clare Bottle’s (CEO UKWA) views on the warehouse of the future, and details of how the inVia Robotics solution can overcome some of the constraints…. from Steve Doster (Senior Enterprise Sales Director – inVia Robotics)

-

Delivering for customers in an ever changing world

In this first of a series of three webinars addressing the challenges facing global supply chains and how automation can help, we were delighted to hear some global supply chain insights from Professor Edward Sweeney (Professor of Logistics and Supply Chain Management at Heriot-Watt University) and the sharing of her experience in delivering robust warehouse…

-

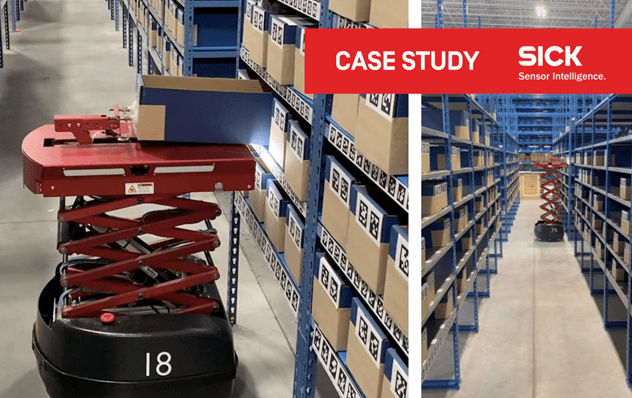

How Sick Sensor Intelligence transformed its fulfilment facility

The Challenge SICK Sensor Intelligence is a leading manufacturer of sensors, safety systems, machine vision, encoders and automatic identification products for industrial applications. The company needed to increase B2B fulfillment speed and accuracy to ensure timely delivery of products to their growing customer base. They sought a solution to enhance process efficiency and reduce the necessity of…

-

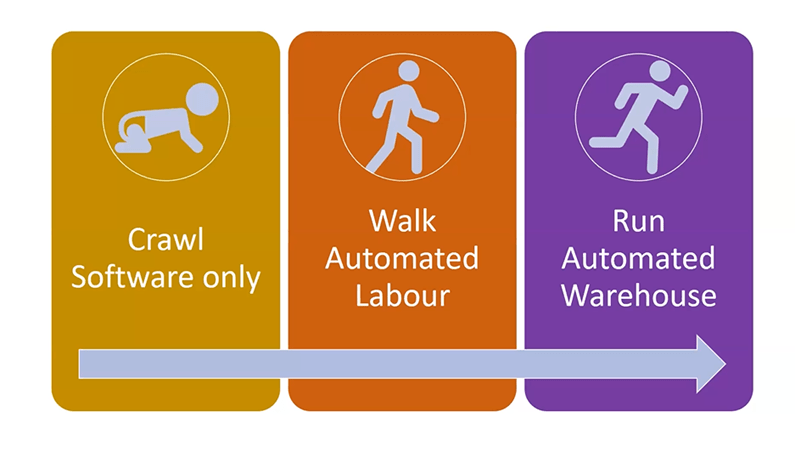

Crawl – Walk – Run

Warehouse automation need not be an expensive ‘Leap in the Dark. inVia Robotics solution allows you to start with its ground breaking AI driven software, and then bring in robotics as and when you are are ready – flexible and scaleable. inVia’s RaaS solution reduces the upfront cost and risk and reduces the payback time…

-

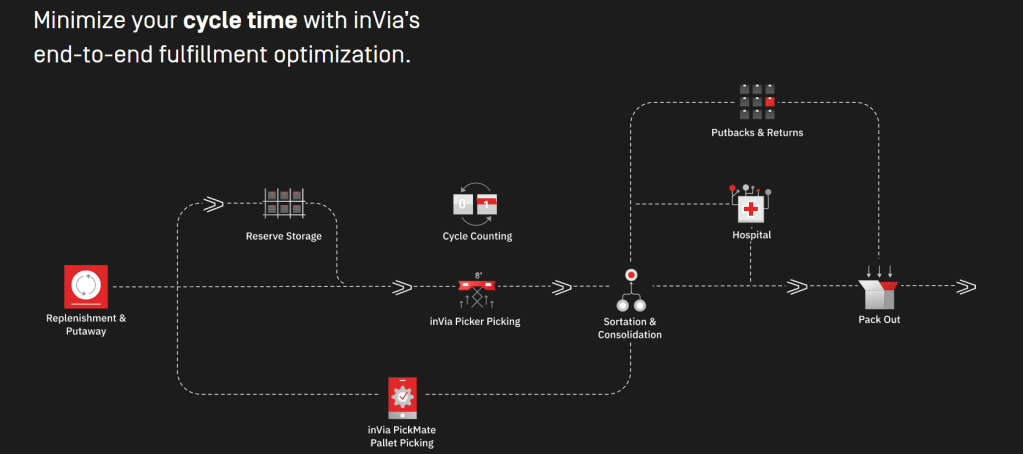

inVia Logic – WES on steroids!

Minimise your cycle time with InVia’s end-to-end fulfilment optimisation. No bottlenecks with the inVia Robotics warehouse fulfilment solution. inVia Logic Software orchestrates and optimises your most valuable assets – inventory, people and robots – in real time, continuously monitoring and refining to maximise efficiency in all fulfilment tasks